The risk of explosion is one of the most critical subjects in an industrial environment. The effects of an explosion can be devastating, both human and material. The risk of explosion is all the more problematic as its phenomenon is instantaneous and irreversible. It is therefore a very sensitive subject that every industrialist must have in mind. Thus, it is the duty of an employer and more particularly in the industrial environment to:

To prevent the risks associated with the presence of explosive atmospheres (ATEX) in the workplace, the French Labor Code for instance defines the ATEX regulations initially resulting from two European directives:

Directive 1999/92/EC requires the employer to:

Directive 2014/34/EU requires manufacturers to only market devices or equipment that comply with the requirements of this same directive if they are intended for use in explosive atmospheres (ATEX). The essential safety requirements of this directive are to use integrated safety against explosions from the design stage, to affix a CE marking to the product, to draw up a written CE declaration of conformity and to produce an instruction manual.

As mentioned above, the regulations require the employer to identify the areas of the workplace where explosive atmospheres (ATEX) can form. These result from a mixture in the air of a combustible substance in the form of gas/vapours or dust, the ignition of which instantly propagates combustion to the entire unburned flammable mixture. For this, it is necessary that the conditions of the explosion hexagon are met.

Indeed, for an explosion to take place, six conditions must be met simultaneously, the first three being those of the fire triangle:

The methodology for classifying ATEX zones is described in standards EN 60079-10-1 for gaseous ATEX and EN 60079-10-2 for dusty ATEX. The general methodology consists in describing the activities and premises presenting an ATEX risk by identifying the products at the origin of an ATEX zone; potential sources of leaks (flanges, valves, valves, etc.), leak conditions (infrequent, frequent, permanent, etc.), dispersion conditions (leak in an open or closed environment, natural or forced ventilation, reliable ventilation system or not…), then to characterize the zone generated (type and extent of the zone). At this stage, a table of ATEX sources must be produced containing all the information needed to define and characterize all the ATEX zones.

There are three types of ATEX zones:

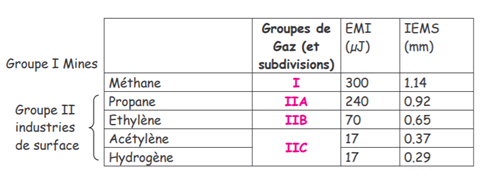

Depending on the product in question, the ATEX zone must also be characterized by the temperature class and the gas group (for gases).

The temperature class is dependent on the autoignition temperature of the product at the origin of the ATEX zoning. The temperature classes are defined as follows:

Note that the characterization of the area will have a direct impact on the type of equipment to be installed (see next chapter)

The extent of an area can be set in 2 ways:

The qualitative method consists in basing oneself on extents of area already known or defined in guides or standards.

The quantitative method consists of using zone extents calculated according to the method described in particular in standard EN 60079-10-1 for gaseous ATEX.

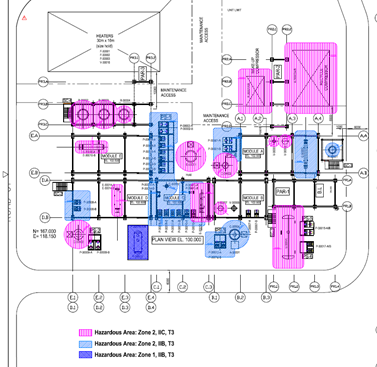

Once the sources of ATEX zoning have been identified and the ATEX zones characterized, they should be identified on the site. First of all, it is necessary to represent them on a plan of the site. Depending on the size of the site, several plans can be made. The idea is to have a precise view of all areas.

Then, in order to identify the areas at risk of explosion called ATEX zone on site, it is necessary to delimit them by a sign (on the ground for example) accompanied by the following pictogram:

After defining the ATEX zones, it is necessary to identify ignition sources. Indeed, an explosion will occur in case of presence of an ignition source. The main sources of ignition observed in industrial environment are :

13 sources of ignition are known and listed in the standard NF 1127-1. Once these ignition sources identified, one of the main measure to prevent explosion is to eliminate them when it is feasible: moving the source, installation of suitable electrical equipment, hot works forbidden…

When the analysis identifies a risk of gas or dust explosion, it is essential for the protection of people and facilities:

In this frame, the implementation of technical and organizational measures is necessary. For instance :

The overall procedure (assessment and prevention of explosion risk) has to formalized into a document called “Explosion Protection Document. Its contents is driven for instance in France by article R.4227-52 of labor code. This document has to be included in the Occupational Risk Assessment of the company and updated every years specifically when :

It is recommended to consult any key people to draw up this document. The document is finalized under the responsibility of employer and submitted for comment to personnel representation entity.

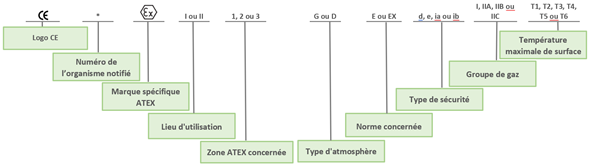

The marking of ATEX equipment indicating the conformity of equipment was introduced with directive 94/9/EC and evolved with directive 2014/34/EU which requires manufacturers to market only compliant devices or equipment. the requirements of the directive, if they are intended for use in explosive atmospheres (ATEX) due to gases, vapors or dust.

Devices falling within the scope of the European directive and meeting the essential health and safety requirements are identified by a marking plate.

This is broken down into several parts:

Figure 1 - Illustration du marquage ATEX

ATEX risk management requires specific skills in order to comply with regulations and ensure optimal protection of workers and equipment.

Whether the site is in the design phase or in operation, SAFENGY puts its technical expertise and all its experience at the service of manufacturers to offer them a complete solution and support them in all their ATEX risk analysis procedures, in particular on the following points :

Complete your team with Safengy engineers

Outsourcing your studies with a lump sum

We intervene according to the way which better matches, lump sum and/or in technical assistance, full or partial time.